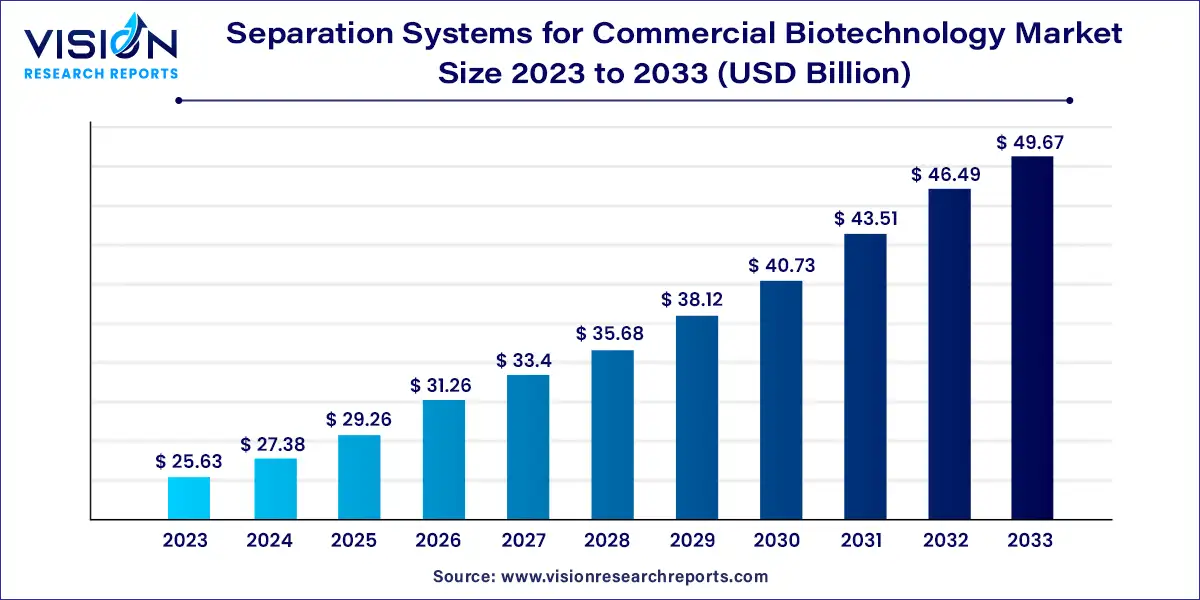

The global separation systems for commercial biotechnology market size is poised to grow by USD 49.67 billion by 2033 from USD 25.63 billion in 2023, exhibiting a CAGR of 6.84% during the forecast period 2024-2033.

The separation systems for commercial biotechnology market is experiencing rapid growth, driven by advancements in biotechnological processes and the rising demand for biopharmaceuticals. These systems play a crucial role in the purification and isolation of biomolecules, cells, and proteins, which are essential for the production of therapeutic agents, vaccines, and diagnostics. The increasing prevalence of chronic diseases, such as cancer and diabetes, has significantly boosted the demand for advanced separation technologies in biopharmaceutical manufacturing. Key methods like chromatography, filtration, and centrifugation are being continuously optimized to meet the growing industry requirements for higher efficiency, scalability, and product purity.

In addition to technological innovations, government support through funding, tax incentives, and streamlined regulatory approvals has positively impacted market expansion. Regions like North America and Europe are leading the market, with well-established biotech industries and strong investment in R&D. Emerging markets in Asia-Pacific are also witnessing substantial growth, driven by increasing biopharma production and favorable government initiatives. The global push towards sustainable biomanufacturing and the rise of personalized medicine further contribute to the ongoing demand for sophisticated separation systems, positioning the market for steady growth in the coming years.

Separation Systems for Commercial Biotechnology Market Highlights:

- Conventional methods held the largest market share of 70% in 2023.

- Modern methods are projected to achieve the highest compound annual growth rate (CAGR) of 7.03% from 2024 to 2033.

- The pharmaceutical sector accounted for the largest market share of 40% in 2023.

- The food and cosmetics sector is anticipated to grow at a CAGR of 7.03% from 2024 to 2033.

Get the Sample Pages of Report for More Understanding@ https://www.visionresearchreports.com/report/sample/41607

Separation Systems for Commercial Biotechnology Market Trends

- Increased Demand for Biopharmaceuticals

The growing prevalence of chronic diseases such as cancer and diabetes has driven demand for biopharmaceuticals, which require advanced separation systems for purification. These systems are essential for the production of monoclonal antibodies, recombinant proteins, and other therapeutic agents.

- Adoption of Single-Use Technologies

Single-use systems are gaining traction in commercial biotechnology due to their cost-effectiveness, flexibility, and reduced contamination risks. These disposable systems are easy to implement in bioprocessing, minimizing cleaning and sterilization needs, which is crucial for separation and purification steps.

- Advances in Chromatography Techniques

Chromatography remains a dominant method in separation systems, with continuous improvements in efficiency, speed, and scalability. Innovations like simulated moving bed chromatography (SMB) and membrane chromatography are making the process faster and more precise, particularly for large-scale production.

- Growth of Downstream Processing

Downstream processing, including filtration, centrifugation, and chromatography, accounts for a significant portion of biotech production costs. As a result, companies are focusing on optimizing separation systems to reduce costs and improve yields, particularly in large-scale biomanufacturing.

- Integration of Automation and Digitalization

Automation and digital technologies are being increasingly integrated into separation systems to improve accuracy and process control. Automated systems allow real-time monitoring and data analytics, ensuring high purity and consistency in biotech products.

- Sustainability and Green Separation Technologies

There is a growing emphasis on developing environmentally friendly separation technologies. Green chemistry principles are being applied to separation systems to reduce energy consumption, waste, and the use of harmful solvents, aligning with sustainability goals in biotechnology.

- Hybrid Separation Techniques

Combining multiple separation methods into hybrid systems is becoming a trend. For example, combining filtration with chromatography helps achieve higher purification levels in a single step, improving efficiency and reducing costs.

Separation Systems for Commercial Biotechnology Market Regional Study

Government Support and Its Impact on the Separation Systems for Commercial Biotechnology Market

Government support plays a critical role in the growth and development of the Separation Systems for Commercial Biotechnology Market.

1. Research and Development (R&D) Funding

Governments worldwide invest heavily in biotechnology R&D, providing grants and subsidies to support innovations in separation technologies. This funding enables academic institutions and private companies to develop advanced separation systems, fostering growth and competition in the market.

- Impact: Increased R&D leads to more efficient and innovative separation systems, such as improved filtration, chromatography, and centrifugation technologies. It also accelerates the commercialization of new products, strengthening the market.

2. Tax Incentives and Subsidies

Many governments offer tax incentives and subsidies to biotechnology companies engaged in manufacturing and developing separation systems. These incentives reduce the financial burden on companies, encouraging investment in advanced technologies.

- Impact: Tax breaks and subsidies lower production costs, making high-quality separation systems more affordable. This promotes widespread adoption, especially among small and medium-sized enterprises (SMEs) in the biotechnology sector.

3. Regulatory Support and Streamlined Approval Processes

Governments are streamlining regulatory processes to encourage the rapid development and approval of biotechnology products, including separation systems. Regulatory agencies such as the U.S. FDA and European Medicines Agency (EMA) have introduced fast-track approvals for biopharmaceuticals, which increases the need for high-quality separation systems.

- Impact: Faster regulatory approvals lead to quicker time-to-market for biotechnology products, driving the demand for efficient and compliant separation systems. Additionally, regulations requiring strict purity and safety standards boost the need for advanced separation technologies.

4. Public-Private Partnerships

Governments are fostering collaboration between public research institutions and private biotech firms through public-private partnerships (PPPs). These initiatives facilitate the sharing of knowledge, resources, and infrastructure, leading to advancements in separation technologies.

- Impact: PPPs lead to breakthrough innovations in separation processes, such as novel filtration and purification techniques. They also help biotech companies access cutting-edge research, enhancing their product portfolios and expanding the market.

5. Support for Biopharmaceutical Manufacturing

Governments recognize the importance of biopharmaceuticals in addressing public health challenges, such as cancer, diabetes, and infectious diseases. As a result, they are investing in infrastructure and providing funding to expand biopharma manufacturing, which directly increases the demand for separation systems used in the production of biopharmaceuticals.

- Impact: Increased investment in biopharma manufacturing boosts the need for efficient separation systems, especially in downstream processing. This trend is driving the growth of the market, as more companies invest in advanced separation technologies to meet production demands.

6. Biotech Industrial Policies and National Biotechnology Strategies

Countries like the U.S., China, India, and Germany have national biotechnology strategies that prioritize the development of the biotech sector, including the infrastructure for biomanufacturing and separation systems. These strategies often include funding, regulatory support, and incentives for domestic biotech industries.

- Impact: National strategies encourage local manufacturing of separation systems, reducing dependency on imports and promoting domestic innovation. This also strengthens the overall competitiveness of the global separation systems market.

7. Focus on Sustainability

Governments are increasingly focusing on sustainable biomanufacturing processes. They are encouraging the development of green separation technologies that reduce energy consumption, water usage, and waste generation. Government grants and policies that promote environmental sustainability in biotech manufacturing are fostering the adoption of eco-friendly separation systems.

- Impact: This push toward sustainability drives demand for greener, more efficient separation systems. Companies that comply with government regulations and produce environmentally friendly systems gain a competitive advantage in the market.

8. Pandemic Response and Vaccine Production

The COVID-19 pandemic highlighted the critical role of biotechnology in vaccine production and therapeutic development. Governments worldwide supported the rapid scale-up of vaccine manufacturing, which required sophisticated separation systems for purification and formulation processes.

- Impact: Increased government investment in pandemic preparedness has expanded the biotech manufacturing infrastructure, including separation systems. This expansion is expected to have a long-term positive impact on the market as biotech companies continue to enhance their production capabilities.

Read More@ Europe Laboratory Developed Tests Market

Top Manufactures in Separation Systems for Commercial Biotechnology Market

- Thermo Fisher Scientific Inc.

- QIAGEN

- Horizon Discovery Ltd.

- OriGene Technologies, Inc.

- Oxford Biomedica PLC

- SignaGen Laboratories

- Flash Therapeutics

- Takara Bio Inc.

- Bio-Rad Laboratories, Inc.

- System Biosciences, LLC.

- Promega Corporation

- F. Hoffmann-La Roche Ltd

- Revvity

- Catalent, Inc

Separation Systems for Commercial Biotechnology Market Segmentation:

By Method

- Conventional Methods

- Chromatography

- Flow Cytometry

- Membrane Filtration

- Electrophoresis

- Centrifugation

- Modern Methods

- Microarray

- Lab-on-a-chip

- Magnetic Separation

- Biochip

By Application

- Pharmaceutical

- Vaccines

- Proteins

- Hormones/Insulin

- Enzymes

- Human Blood Plasma Fractionation

- Mammalian Cell Cultures

- Food & Cosmetics

- Agriculture

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa (MEA)

Buy this Premium Research Report@ https://www.visionresearchreports.com/report/checkout/41607

You can place an order or ask any questions, please feel free to contact sales@visionresearchreports.com| +1 650-460-3308